INTRODUCTION

Wire ropes deteriorate for many reasons resulting in a decrease in strength over their lifetime. For safe operation, wire ropes should be periodically inspected and discarded at the appropriate time - premature discard of a wire rope is wasteful and costly. Comparing inspection data with the discard values contained in the appropriate standard, allows the duty holder to make an informed decision whether to discard the rope or allow it to remain in service.

INTRON PLUS

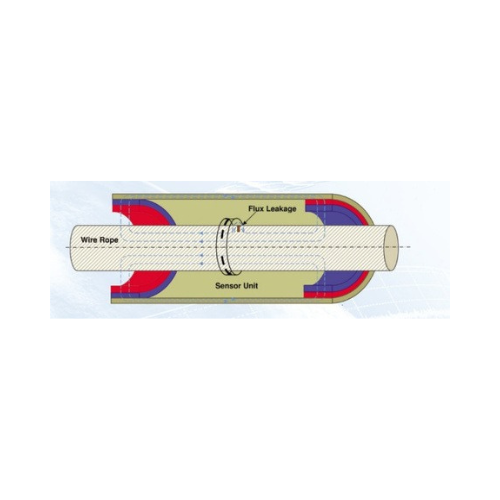

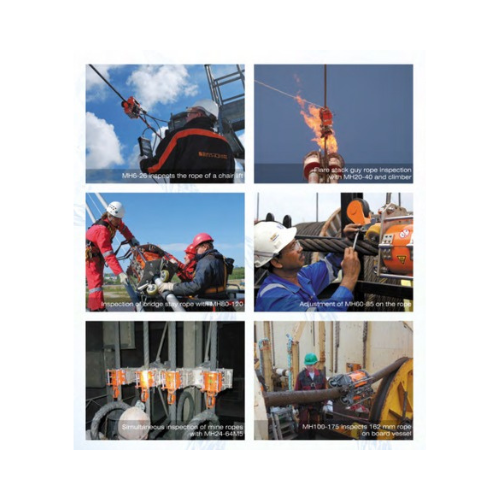

Presents state-of-the-art instruments INTROS® for the non-destructive testing (NDT) of steel wire ropes. INTROS covers a wide range of rope diameters, and can be used for rope inspection in mines, cranes, elevators, ropeways, bridges, overhead transmission lines, etc. INTROS® is dual function instrument, i.e. it simultaneously measures loss of metallic area (LMA), caused by corrosion, abrasion or wear and reveals local flaws (LF) in the form of internal and external broken wires, pitting corrosion, cross-nicking, welding spots, etc. INTROS® is suitable to inspect stranded, spiral, half-locked, full-locked, plastic coated or plastic filled valley ropes made from bright and galvanized wire, with fiber or steel core. It meets the requirements of ASTM E1571, ISO 4309, EN 12927, IMCA LR 004, IMCA HSSE 023, and IMCA M 197.